5-SIDED CNC VS. SIMULTANEOUS 5-AXIS CNC

There are pros and cons to both 5-sided CNC machining and 5-axis CNC machining.

5-SIDED CNC (3+2)

- Simple to program

- Cuts faster

- Fewer concerns about tool interference

- Excellent roughing strategy

SIMULTANEOUS 5-AXIS CNC (FULL 5-AXIS)

- Better surface finish

- Longer tool life

- Allows tool to reach difficult places smoothly

- Impressive but slow – avoid if possible

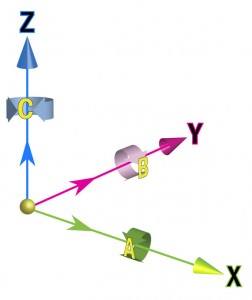

Basics of axis configuration

To understand machine configurations, it’s important to understand the basic terminology of 5-axis machining centers. If you think in terms of a 3-axis machining center, it has an X-axis, Y-axis, and Z-axis. With a 5-axis machining center, the additional rotary axes will rotate about two of those three primary axes.

The axis that rotates about or under the Z-axis is called the C-axis.

The axis that rotates about the Y-axis is called the B-axis.

The axis that rotates about the X-axis is called the A-axis.