According to “Top Shops” benchmark data compiled by Modern Machine Shop, 24 percent of highest-performing machine shops use five-axis positioning, while 16 percent use full five-axis contouring.

The Modern Machine Shop editor asked shop owners how they are benefiting from 5-axis and if they don’t use 5-axis right now, are they considering it in the future. Several shop owners commented on the large size of their NC programs. Their comments made me think of a feature called Tool Path Linearization (Hurco 5-axis control feature), which significantly reduces the file size while improving surface finish.

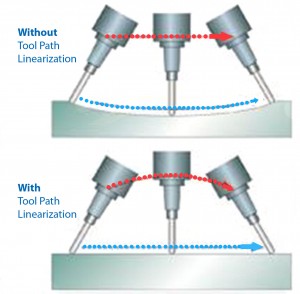

Behind the CNC so ftware / how it works The tool tip basically attaches itself to the workpiece instead of blindly following the rotations commanded by the CAM system. The tool tip and tool vector are interpolated between tool positions with respect to the workpiece, even with the tool and part rotating inside the machine.

ftware / how it works The tool tip basically attaches itself to the workpiece instead of blindly following the rotations commanded by the CAM system. The tool tip and tool vector are interpolated between tool positions with respect to the workpiece, even with the tool and part rotating inside the machine.

How Tool Path Linearization benefits you: this feature eliminates gouging of the workpiece and the line segments in the form of XYZBC or AC moves that a CAM system uses (the looping patterns on the part). Therefore, your part has a better surface finish and the program is optimized, which reduces the file size. Click here to watch a brief video explanation.

Click here to read shop owners’ thoughts about 5-axis at the Modern Machine Shop blog.